Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a “weir or saddle” or seat upon which the diaphragm closes the valve. The valve is constructed of plastic or metal. Originally, the diaphragm valve was developed for use in industrial applications. Later, the design was adapted for use in the biopharmaceutical industry using compliant materials that can withstand sanitation and sterilization methods.

The diaphragm valve has its origins in Roman and Greek times, where it was used to control the water and temperature of hot baths. With a rawhide diaphragm that was manually closed over a weir, it was a primitive but effective control valve. In addition to the well-known two-way stop valve, other types include: three-way zero-check valve, sterile access port, block and purge, bottom valve, and bottom of vessel.

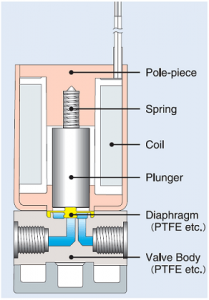

Sanitary diaphragm valves can be manual or automated. Their application is generally as shut-off valves in processing systems in the industrial, food and beverage, pharmaceutical and biotechnological industries. The older generation of these valves is not suitable for regulating and controlling process flows, but new developments in this area have successfully solved this problem.