(1) Truncated type: gate valves, globe valves, cock valves, sanitary ball valves, sanitary butterfly valves, needle valves, sanitary diaphragm valves, etc. Truncated valves are also known as closed-circuit valves, and their functions are to connect or cut off the medium in pipelines.

Sanitary check valve, belonging to an automatic valve, its role is to prevent the medium in the pipeline backflow, prevent the reversal of the pump and drive motor, and container media leakage. The bottom valve of the water pump is also a check valve.

The function of the safety valve is to prevent the medium pressure of the pipeline or device from exceeding the prescribed value, so as to achieve the purpose of safety protection.

The function of regulating valve, throttle valve, and pressure reducing valve is to regulate the pressure and flow rate of the medium.

(2) Vacuum type: vacuum ball valve, vacuum baffle valve, vacuum charging valve, pneumatic vacuum valve and so on. Its function is in the vacuum system, used to change the direction of the airflow, adjust the size of the air flow, cut off or close the pipeline vacuum system components called vacuum valves.

(3) Special types: pigging valves, vent valves, drain valves, exhaust valves, filters, etc. The exhaust valve is an indispensable auxiliary component in the pipeline system, which is widely used in boiler, air conditioning, oil and natural gas, water supply, and drainage pipelines. Often installed at the commanding height or elbow, eliminate excess gas in the pipeline, improve the efficiency of pipeline use and reduce energy consumption.

Gate valve

The gate valve is used as a cut-off medium, in full open when the whole flow through, at this time the media operation of the minimum pressure loss. Gate valves are usually applied to do not require frequent opening and closing, and maintain full or full closing of the gate. It is not suitable for regulating or throttling use. For high-speed media, the vibration of the gate may be caused by the local opening of the gate, and the vibration may damage the sealing surface of the gate and the valve seat, and the throttle will cause the gate to be eroded by the medium. From the structural form, the main difference is the form of the sealing element used. According to the form of sealing elements, gate valves are often divided into several different types, such as wedge gate valves, parallel gate valves, parallel double gate valves, wedge double gate valves, etc. The most commonly used forms are wedge gate valves and parallel gate valves.

Globe valve

The valve stem axis of the globe valve is perpendicular to the sealing surface of the valve seat. Stem opening or closing stroke is relatively short, and has a very reliable cut-off action, making this Voto valve very suitable for medium cut-off or adjustment and throttling use. Once the disc of the globe valve is opened, there is no contact between the seat and the sealing surface of the disc, and the valve has a very reliable cut-off action, so this valve is very suitable for medium cut-off or adjustment and throttling use.

Butterfly valve

The butterfly valve is simple in structure, small in size, and light in weight. It consists of only a few parts. Moreover, the valve can be opened and closed quickly with only 90 degrees of rotation, and the operation is simple. At the same time, the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium flows through the valve body, so the pressure drop produced by the valve is very small, so it has good flow control characteristics. The butterfly valve has two types of sealing: A bullet seal and a metal seal. The elastic sealing valve can be inlaid on the valve body or attached to the periphery of the butterfly plate.

Metal sealed valves are generally longer than elastomeric sealed valves, but it is difficult to completely seal them. The metal seal can adapt to higher working temperatures, and the elastic seal has the defect of temperature limitation.

If a butterfly valve is used as flow control, the main choice is to choose the size and type of valve correctly. The structural principle of the butterfly valve is especially suitable for making large caliber valves. Butterfly valves are not only widely used in petroleum, gas, chemical industry, water treatment, and other general industries, but also used in the cooling water system of thermal power plants.

The butterfly valve is connected between two pipe flanges by double-head bolts. The flanged butterfly valve is flanged on the valve. The flanges on both ends of the valve are connected to the pipe flange by bolts.

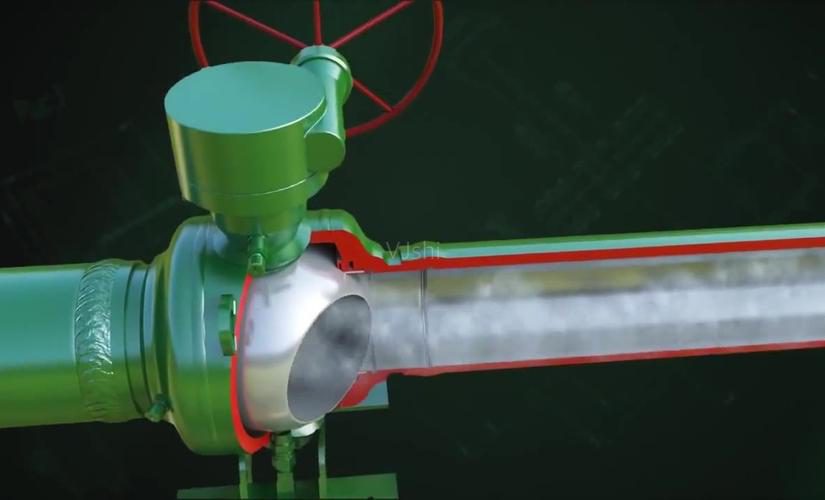

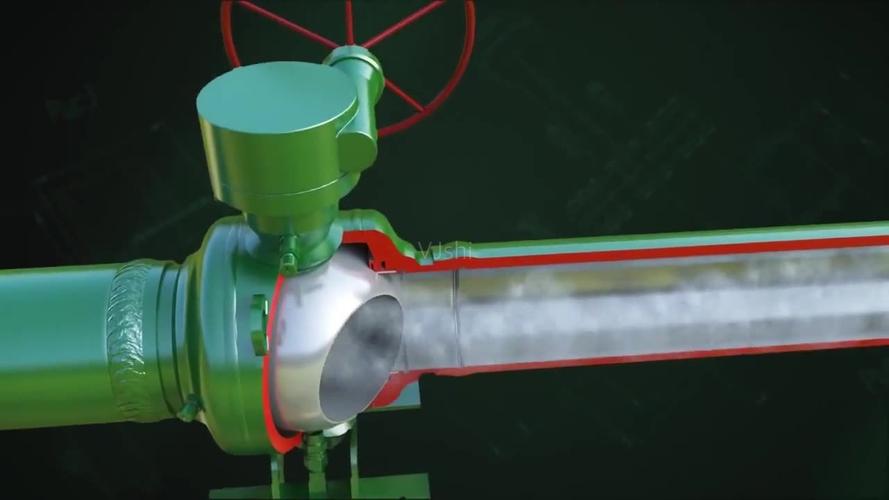

Ball valve

The ball valve evolved from the stopcock. It has the same 90-degree rotation lifting action, the difference is that the cock is a sphere, with a circular hole or passage through its axis. The ratio between the sphere and the port should be such that when the sphere rotates 90 degrees, the inlet and outlet should be all spherical, thus cutting off the flow.

The valve can only be closed with 90 degrees of rotation and very small torque. A perfectly equal valve body cavity provides a very small and direct flow passage for the medium. Ball valves are generally considered to be most suitable for direct open and close use, but recent developments have designed them for throttling and flow control purposes. The main feature of the ball valve is its compact structure, easy operation, and maintenance, suitable for water, solvent, acid and natural gas, and other general working media, but also suitable for working conditions of poor media, such as oxygen, hydrogen peroxide, methane, and ethylene. The ball valve body can be integral or modular.